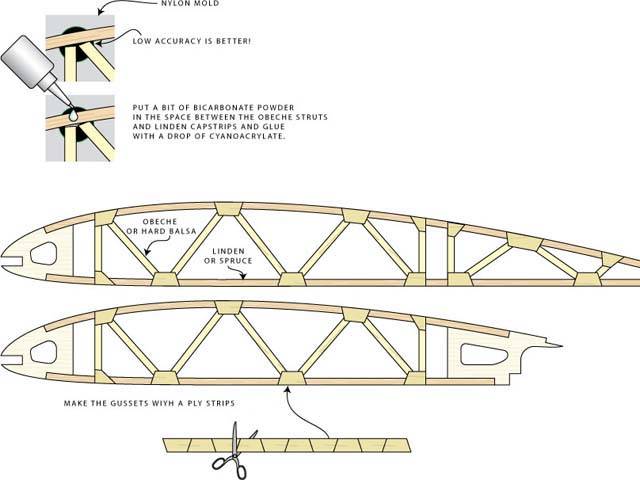

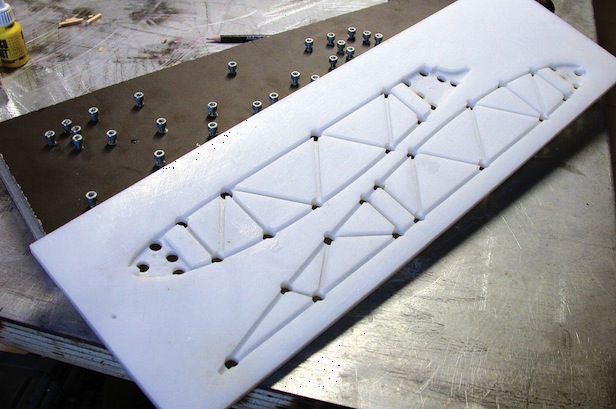

I milled a mold reproducing the rib structure with a CNC pantograph, from a 10 mm thick nylon sheet. I then drilled a 10mm hole at each intersection of the structure. I made then a sort of extractor screwing on a piece of chipboard some 6mm screws, having hexagonal head, so to match the holes on the nylon templates.

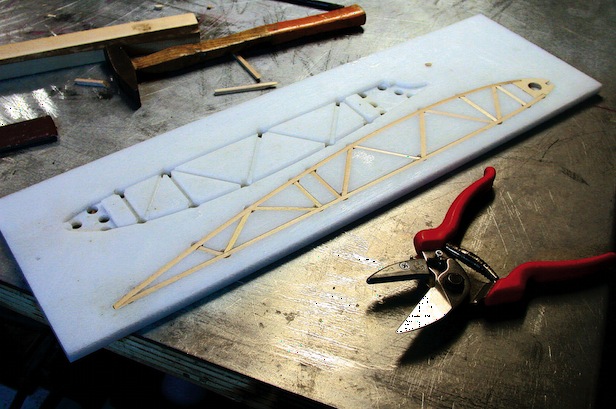

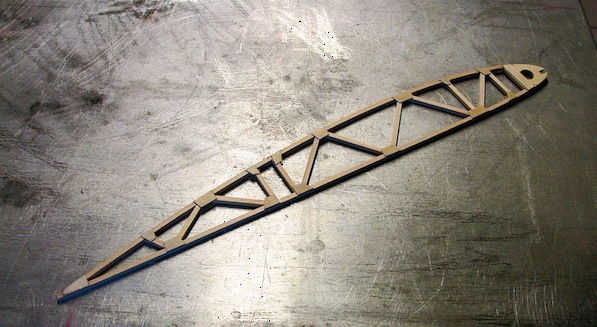

To build the rib I inserted lists (3x3 or 4x4 mm in accordance to scale) the cut outs, top and bottom are linden or spruce wood, obeche or hard balsa for the cross braces, and for the front of the rib I used poplar plywood cut on the pantograph.

The whole thing is pushed all the way down precisely into the template, then I dripped some drops of CA on each intersection of the structure, using also the 10mm holes so to add some CA drop from the bottom

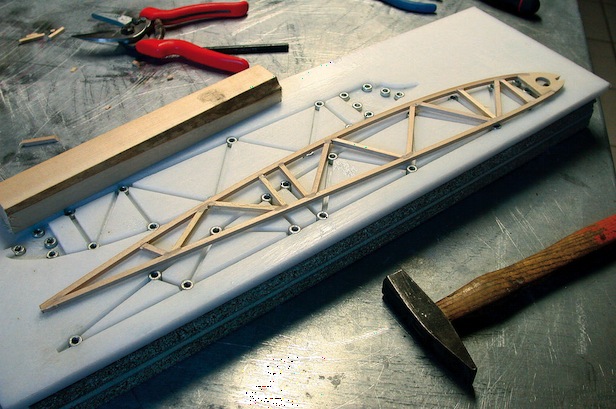

After few minutes I layed the template on the extractor and by hammering the nylon slightly the rib came out of the template perfectly glued.

The addition of 0,6mm birch plywood plates has even overstrengthened the whole part.

The weight of each rib is almost the same of the rib made in lightened poplar plywood but with a far superior strength.

Some suggestion